After distribution, consumption and use, plastic products can be physically recycled or chemically recycled to obtain post-consumer recycled material (PCR). Compared to virgin material, the structure and properties of PCR have changed--on one hand, the structure of PCR becomes unstable, posing challenges for mold design and injection molding process control; on the other hand, the appearance and performance defects of PCR make it difficult to be used in high value-added products, and it is often used in lower-end application scenarios. In the current environment, the cost of recycling and regranulation of plastics is high, so the price of PCR is inherently higher than virgin material. If we cannot control the tooling and production process cost of PCR products, and cannot explore the high value-added applications of PCR, it will be difficult to promote PCR in the market on a large scale.

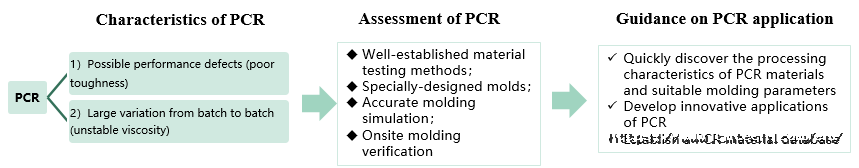

In view of the possible deterioration of appearance and toughness of PCR materials, as well as unstable structure and properties from batch to batch, before using a PCR material, it is necessary to make an accurate and complete evaluation of the PCR material to determine whether the PCR material is suitable for specific applications and how to achieve better molding. Based on this background, we developed a PCR material evaluation system.

The evaluation system mainly consists of three steps.

Firstly, the CAE data test and basic performance test of PCR are carried out. The CAE data test is to generate a MTR data package for subsequent molding simulation analysis. The basic characterization test focuses on assessing changes in toughness and flowability of PCR. In most cases, the fluidity of PCR materials will become better and the toughness will be worse. Better flowability may be suitable for thin-walled applications, while materials with lower toughness should be used with caution in structural parts.

Secondly, molding simulation analysis is performed in our specially designed experimental molds. Through molding simulation, the characteristics and appearance changes (filling, sink mark, warpage, etc.) of PCR can be investigated, which can be used to guide the molding conditions. In particular, the flow filling behavior of different batches of PCR of the same grade may be different, resulting in differences in the molding parameters.

Finally, on-site molding trial verification is carried out.

Based on the evaluation of different PCR materials, especially through molding simulation analysis, firstly we can more quickly discover the processing characteristics of PCR materials and suitable molding parameters, and also find innovative applications of PCR materials. And secondly we can establish a PCR material database (containing viscosity data of commonly used PCR materials, as well as MTR data packages), which can be used for molding simulation and material selection for different applications of different customers.